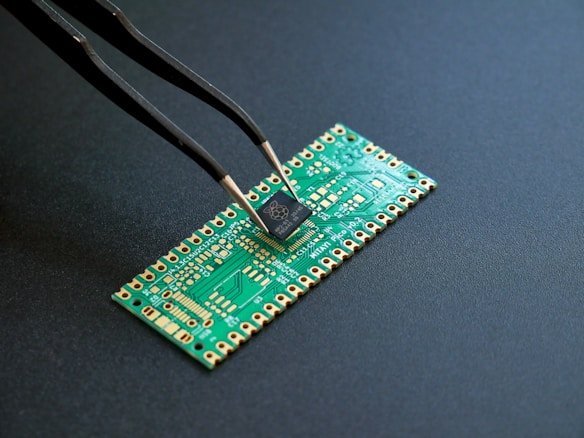

A PCB (Printed Circuit Board) is a key component in modern electronics. It is a flat, insulating board layered with conductive pathways made of copper, used to connect electronic components mechanically and electrically. Here’s a detailed breakdown:

What Is a PCB?

- Purpose: Serves as a foundation for mounting and interconnecting electronic components.

- Construction:

- Made from non-conductive substrates (e.g., fiberglass or epoxy resin).

- Contains copper layers etched to form pathways (traces) that direct electrical currents.

- Includes protective layers like solder mask and silkscreen.

Common Types of PCBs

- Single-Sided PCB:

- One layer of copper on the substrate.

- Used in simple devices like calculators and power supplies.

- Double-Sided PCB:

- Copper layers on both sides, connected via holes.

- Suitable for more complex circuits like LED systems.

- Multilayer PCB:

- Multiple layers of copper and insulation, laminated together.

- Ideal for high-speed and compact electronics like smartphones.

- Rigid PCB:

- Made with stiff materials to provide structural integrity.

- Used in medical devices and industrial machinery.

- Flexible PCB:

- Constructed on flexible materials, allowing bending and folding.

- Found in wearable devices and foldable displays.

- Rigid-Flex PCB:

- Combines rigid and flexible sections.

- Common in aerospace and military applications.

Main Components of a PCB

- Substrate: The non-conductive base.

- Copper Layer: Conducts electricity.

- Solder Mask: Protects copper traces from oxidation.

- Silkscreen: Adds labels for components and assembly.

Applications of PCBs

- Consumer Electronics: Smartphones, televisions, and laptops.

- Medical Devices: Pacemakers and diagnostic equipment.

- Automotive: Engine control units and sensors.

- Aerospace: Navigation systems and satellites.

PCBs revolutionized electronics by enabling compact, durable, and efficient designs. As technology advances, PCBs continue to evolve with innovations like HDI (High-Density Interconnect) and flexible circuits.